Transform your concepts into production-ready designs with our collaborative engineering approach. Our team works with you to refine ideas, develop detailed specifications, and ensure manufacturability from the start.

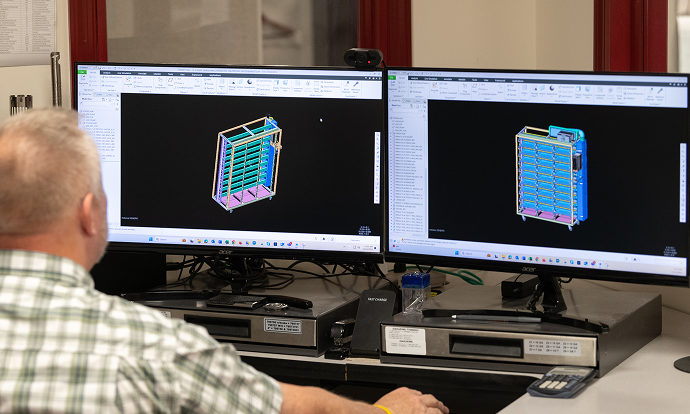

Visualize your components with precise technical drawings and digital models. Our advanced CAD capabilities allow us to create exact virtual representations before manufacturing begins, reducing errors and improving efficiency.

Test and refine your designs before committing to full production. Our prototyping services allow you to validate form, fit, and function while minimizing risk and optimizing your design for large-scale manufacturing.

Create intricate shapes and detailed components with our state-of-the-art laser cutting technology. We handle both flat sheet metal and complex tube cutting with exceptional accuracy and consistent edge quality.

Join materials flawlessly with our certified welding processes for carbon steel, stainless steel, and aluminum applications. Our expertise ensures structural integrity and appearance quality across all welded components.

Shape your metal components with precision using our advanced CNC equipment. From cost-effective punching operations to complex forming and bending, we maintain tight tolerances and consistent quality throughout production.

Transform individual components into finished products with our comprehensive assembly capabilities and finishing options including painting, polishing, and surface treatments to enhance both appearance and performance.

Navigate material selection with expert guidance on optimal materials for performance, durability, and cost-effectiveness. Our materials knowledge helps you make informed decisions that impact your product’s success.

Establish long-term production partnerships with consistent quality standards. Our contract manufacturing services provide reliable production capacity with the flexibility to adapt to changing requirements.

Ensure specification compliance through rigorous testing and inspection protocols. Our comprehensive quality control systems verify that every product meets or exceeds your standards before leaving our facility.

Access quality materials at competitive prices through our established supply chain relationships. Our strategic sourcing capability ensures material availability and cost optimization for your manufacturing projects.